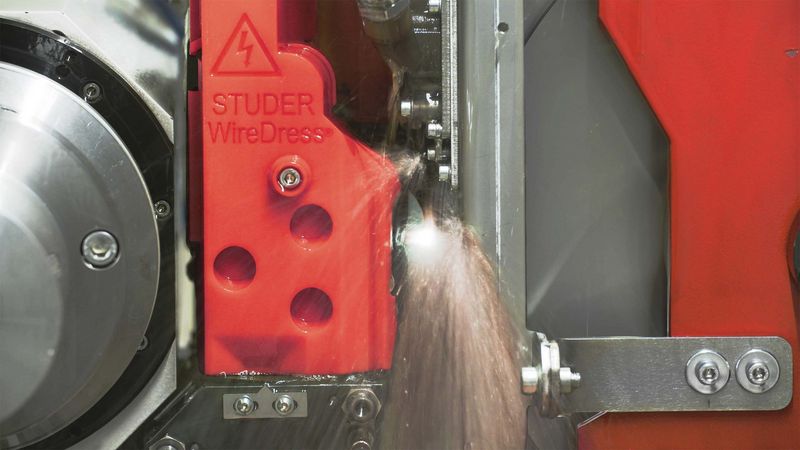

STUDER WireDress®

The integrated electro-discharge dressing technology WireDress® opens up brand new possibilities for grinding with metal-bonded grinding wheels and drastically cuts auxiliary times.

Metal-bonded grinding wheels are used to machine difficult-to-machine materials such as high-alloy, hardened steels, tungsten carbides and ceramics, as they are offer superior dimensional and thermal stability. However, there are also disadvantages in using metal-bonded grinding wheels. Dressing these wheels involves greater expense and effort. External dressing machines are sometimes used for dressing, creating huge demands on handling and logistics. Complex, intricate profiles cannot be dressed economically in this way.

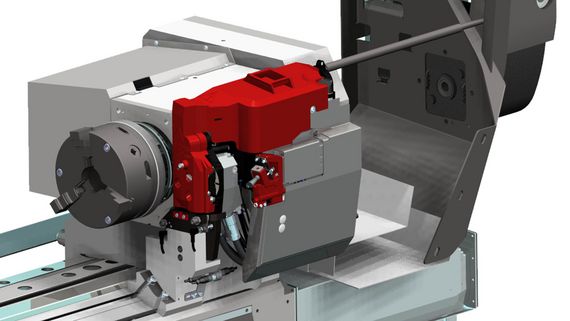

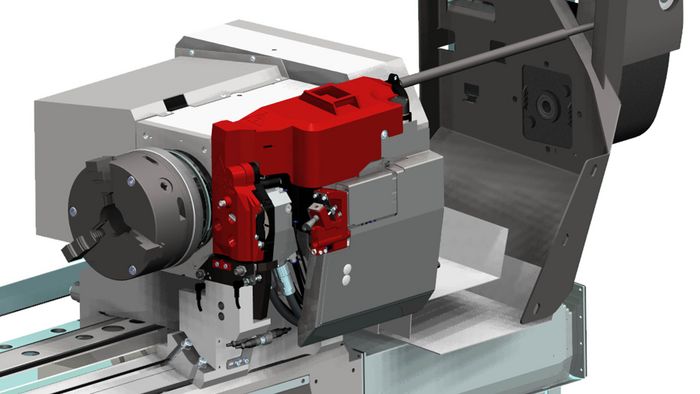

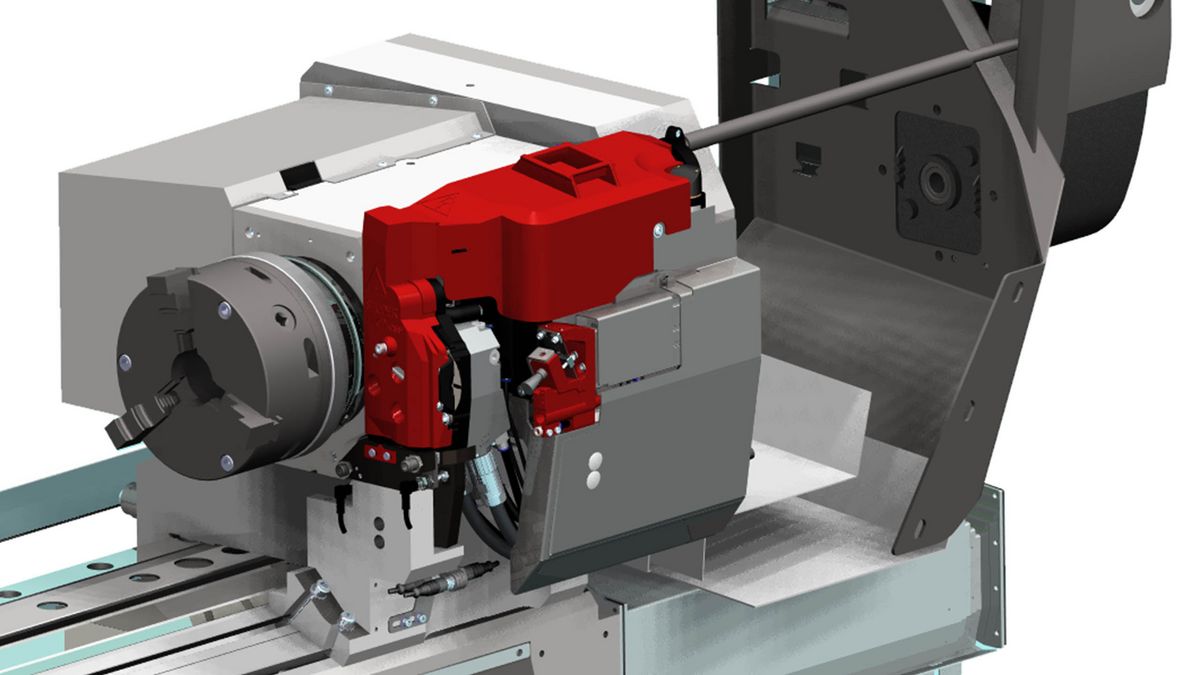

With WireDress® STUDER brings a brand new dressing device to the market, which is completely integrated into the cylindrical grinding machine and its control system. Laborious dismounting and resetting of the grinding wheel during reassembly after external dressing is no longer necessary.

Key features of WireDress®

Higher productivity

- At least + 30% sanding capacity

- Longer dressing intervals

- Highest grain clearance> max. sleekness

- Dressing in the grinding machine> higher OEE

- Low dressing tool costs

High precision

- No wear on the dressing tool

- Turnable dresser

- Dress 20% faster metal bond

- Highest profile precision achievable in the μm range

- -75% disc wear with metal binding

- -70% workpiece displacement

- At workpiece R inside 0.2 mm R outside 0.05 reachable

Easy handling

- Full range usability

- Fully integrated in StuderWIN machine control

- Regular grinding oil can be used

- Touchdressing usable

- Quick change of wire coil without re-registering