The ergonomic machine for

the entry-level segment.

Basic Data

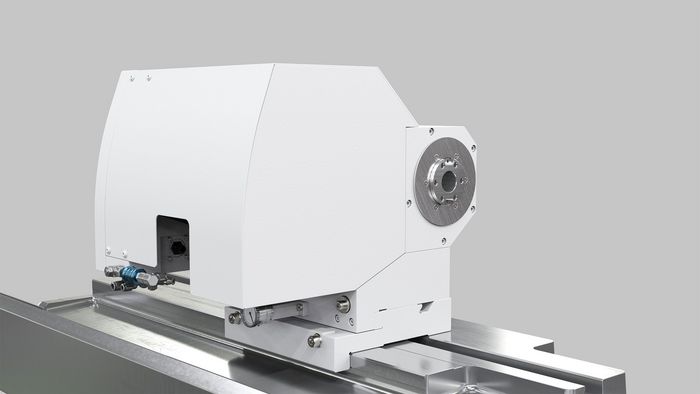

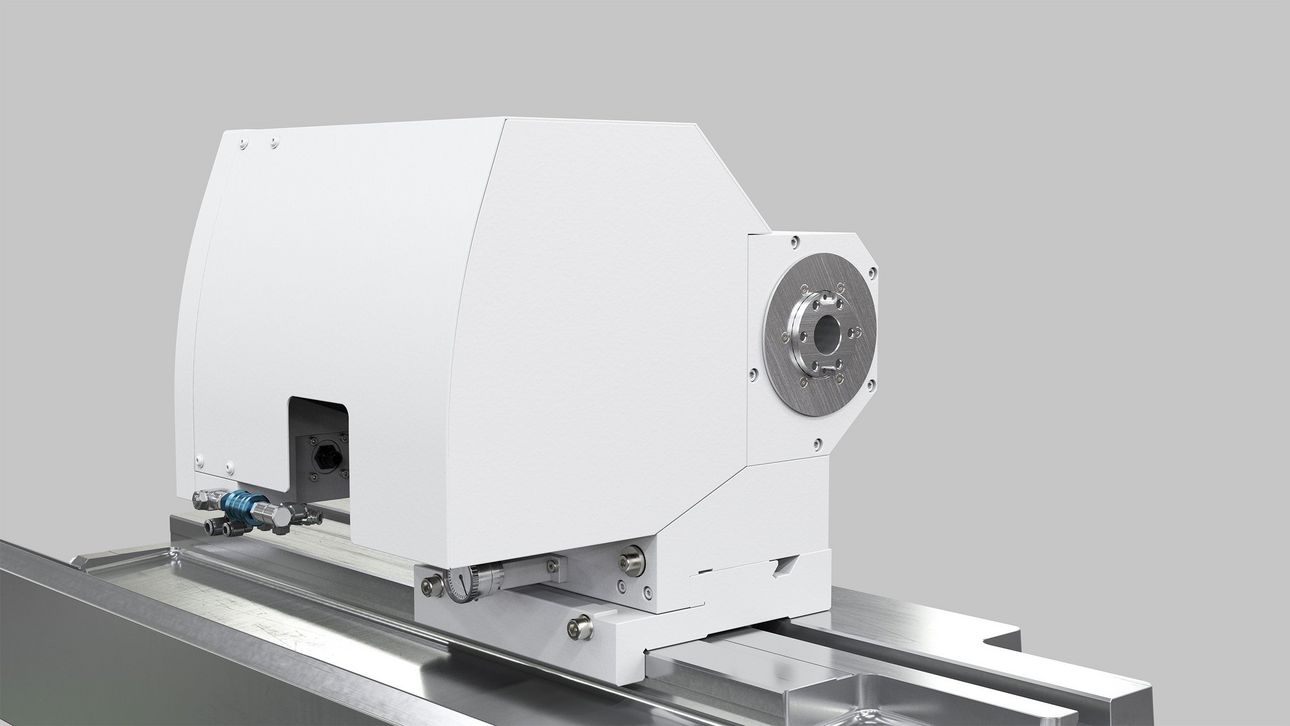

The S100 CNC universal internal cylindrical grinding machine offers the proven STUDER quality and highest precision in standard internal cylindrical grinding operations at an excellent price-performance ratio. It covers the wide range of internal, surface and external grinding applications. This makes it the ideal universal internal cylindrical grinding machine for the entry-level segment.

It has a workpiece length including clamping device of max. 550mm (21.65") and a workpiece diameter of max. 420 mm (16.53"). Many suitable workpieces can be found in the compressor, hydraulic, machine tool, aerospace and tooling industries.

Images

Hardware / Software

Hardware:

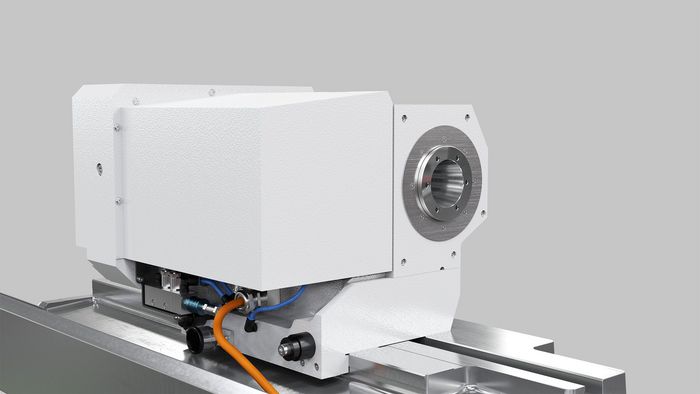

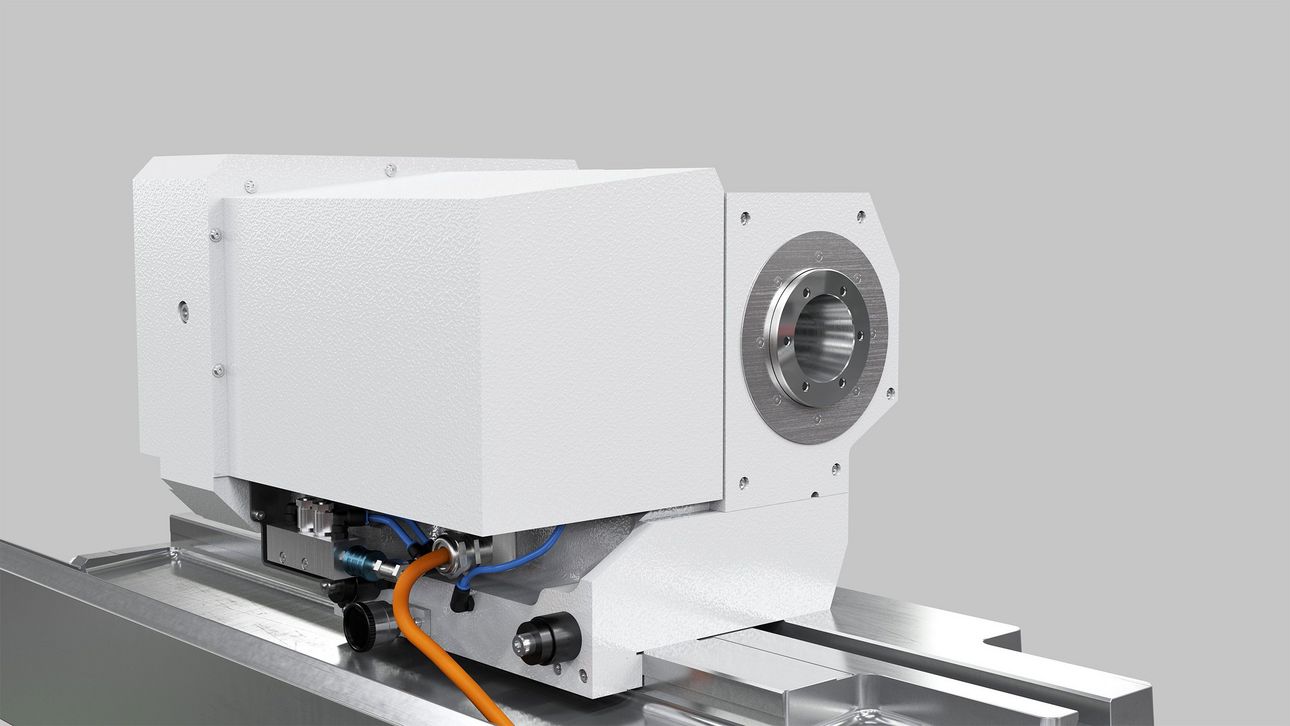

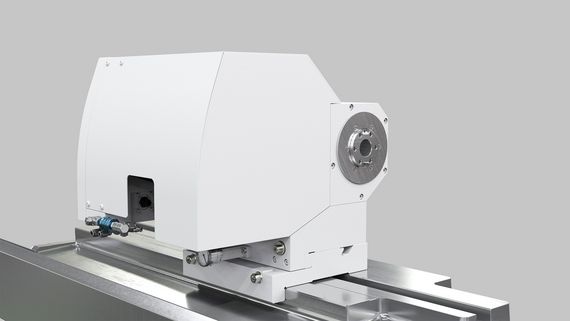

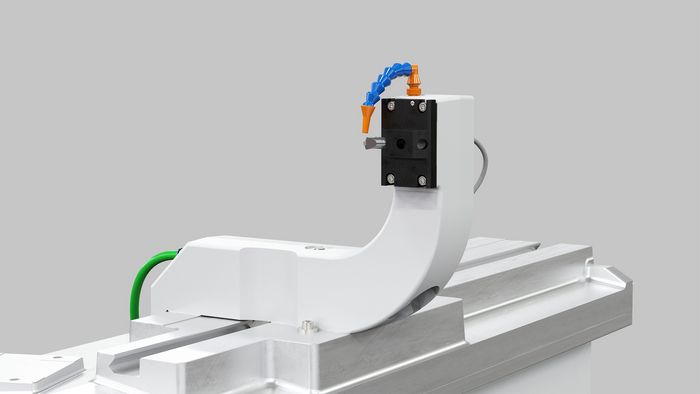

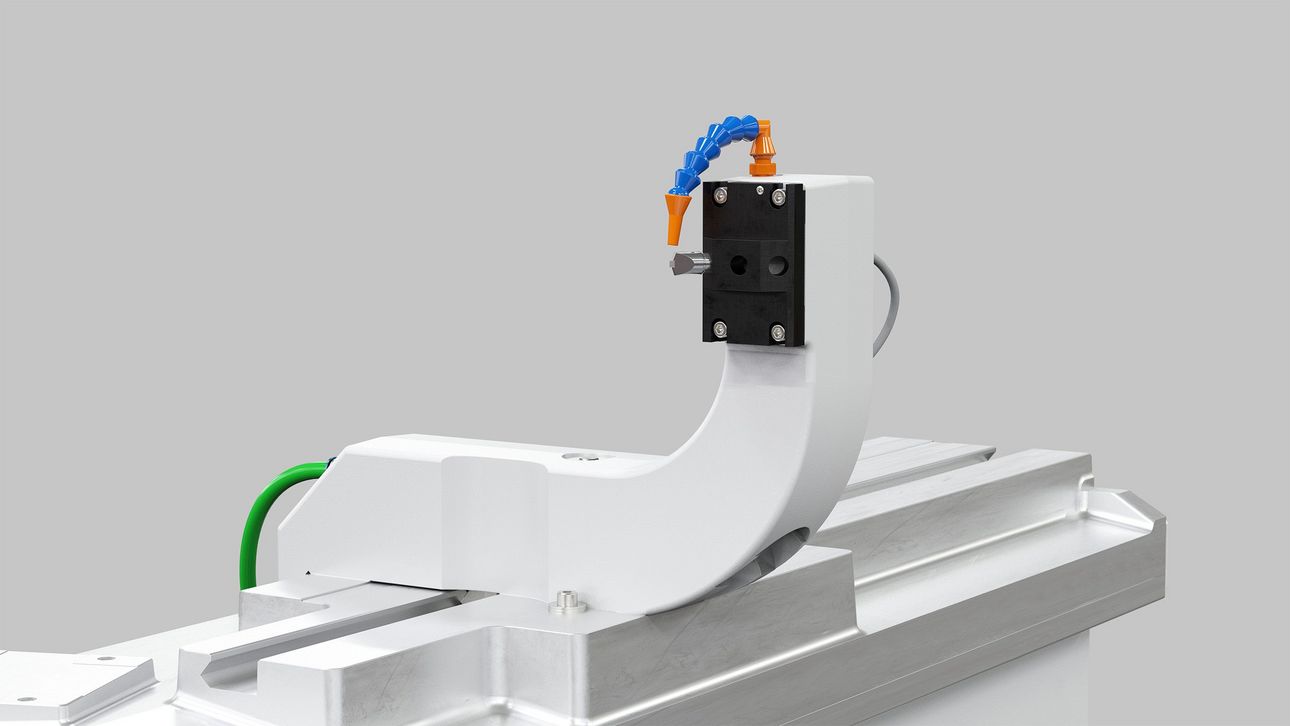

- Grinding spindle turret either with 2.5° Hirth manual

or 1° Hirth automatic - Frequency-controlled belt spindles for external and internal grinding

up to 60 000 rpm - Manual control unit for set-up close to the grinding process

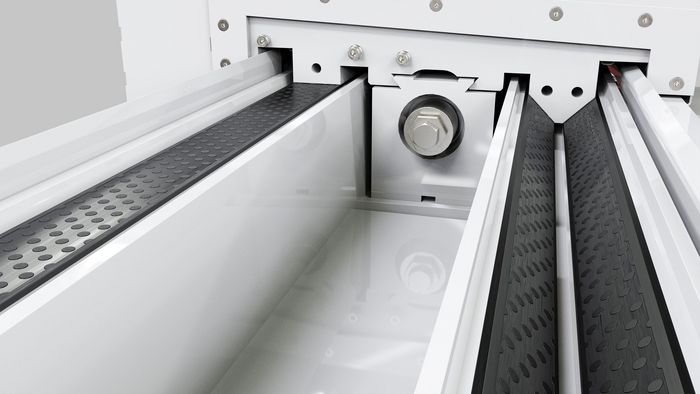

- Granitan® S103 mineral casting machine base

Software:

- StuderPictogramming: Programming support using pictograms

- Operator-guided set-up

- Manual grinding cycle for one workpiece seat

- Short set-up and changeover times with STUDER QuickSet and

automatic grinding spindle turret

Technical Data

Linear Axes

Max. Travel X

285 mm

Max. Travel Speed X

10'000 mm/min

Max. Travel Z

800 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

6.8 kW

Max. Number Of Revolutions

60'000 /min

Max. Grinding Wheel Diameter

400 mm

Max. Grinding Wheel Width

40 mm

Swiveling Axes

Swiveling Range B

-10 – +190 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

550 mm

Workpiece Diameter

420 mm

Center Height

225 mm